Hydraulic Compressors:

our Idro side

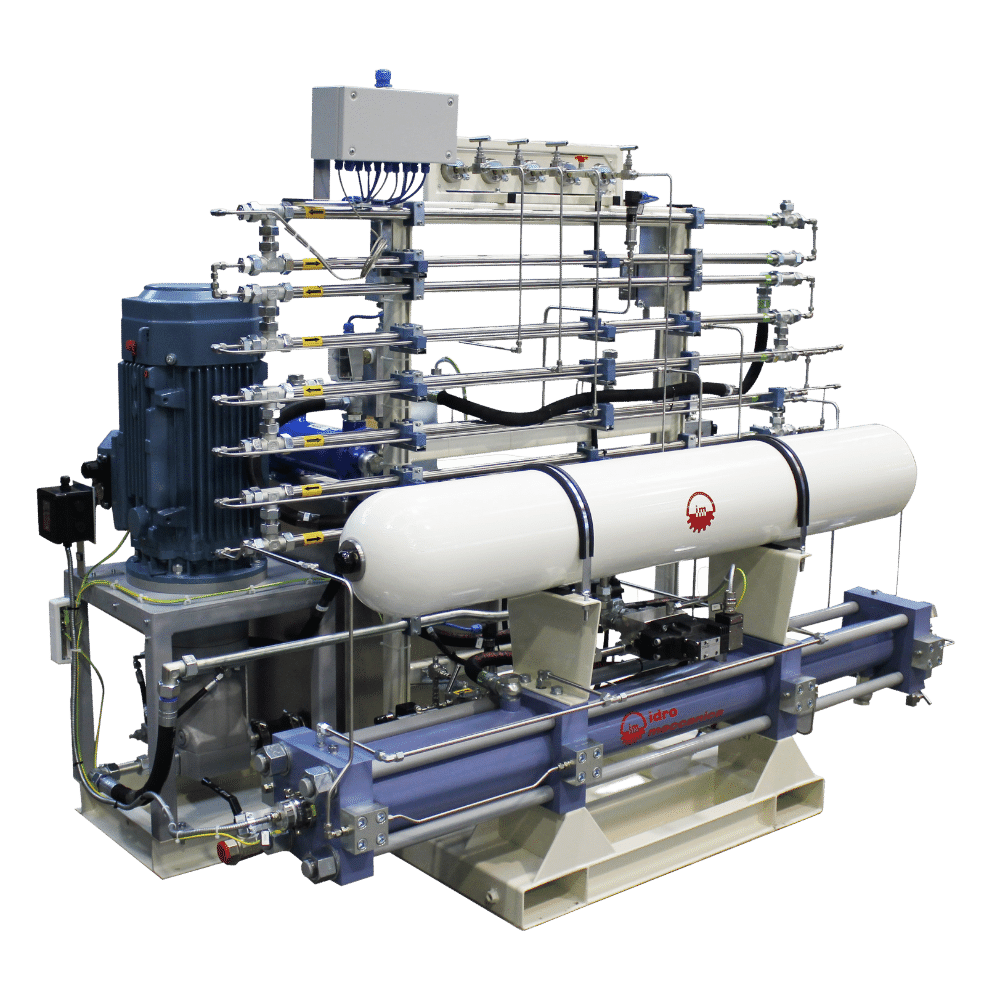

Our compressor units feature hydrostatic transmission.

The heart of the compressor are cylinders in single or twin configuration.

A steel rod connects the oil piston with the two gas pistons.

The only moving part is the connecting rod

It is a simple structure. The pressure of the oil drives the cylinder

Cooling system

Idro Meccanica compressors are water-cooled. The gas and oil are cooled by heat exchangers while the gas cylinders have a cooling jacket. The cooling circuit is completed with a radiator and a circulation pump.

maintenance

Installation and maintenance: what you need to know

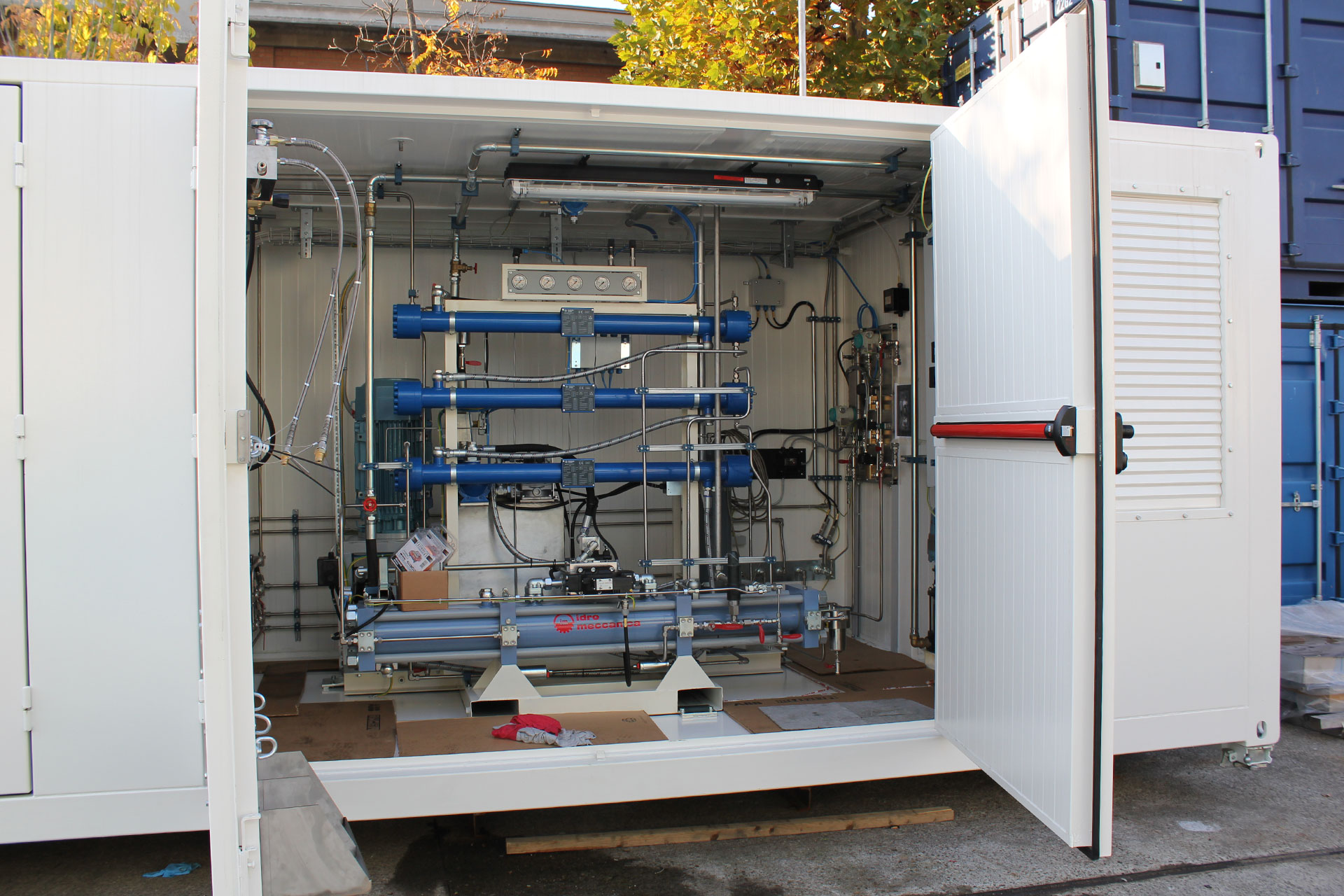

The compression units are supplied mounted on a steel frame.

No foundations are required: the units can be placed directly on the existing baseplate.

The gas cylinders are not lubricated and their inner surface is chrome-plated.

The inlet and outlet valves of each compressor stage are maintenance-free: they do not require any check.

The parts subject to wear are the seals:

| Seals | Type | Life-cycle |

|---|---|---|

| gas side | Made of special PTFE (Teflon) self-lubricating compound | ~ 5000 running hours |

| oil side | hydraulic type | ~ 10.000 running hours |

maintenance

Installation and maintenance: what you need to know

The compression units are supplied mounted on a steel frame.

No foundations are required: the units can be placed directly on the existing baseplate.

The gas cylinders are not lubricated and their inner surface is chrome-plated.

The inlet and outlet valves of each compressor stage are maintenance-free: they do not require any check.

The parts subject to wear are the seals:

| Seals | Type | Life-cycle |

|---|---|---|

| gas side | Made of special PTFE (Teflon) self-lubricating compound | ~ 5000 running hours |

| oil side | hydraulic type | ~ 10.000 running hours |

Safety

Safety

All electrical apparatus on the compressor are designed to be used in a Z2 (Z1 upon request) hazardous area.

The electric motors are explosion-proof and all instruments are intrinsically safe fed.

The units are not equipped with venting lines. The compressor remains pressurised at all times.

Each compressor is complete with everything necessary for smooth and safe operation.

Three families - unlimited customisation possibilities

The great flexibility of Idro Meccanica compressors allows us to customise the entire system according to the customer's requirements. We choose the best solution in terms of efficiency and performance with highly competitive OPEX and CAPEX.

General performance throughout the hydrogen value chain

We offer highly available and reliable compression units with low running costs and high performance throughout the hydrogen value chain.

| Applications | Pressure range (bar) | Pressure range (psi) |

|---|---|---|

| Hydrogen industrial use | From 4 to 250 bar | From 58 to 3.625 psi |

| Grid injection and cylinder tank refilling | From 75 to 450 bar | From 1.088 to 6.525 psi |

| Hydrogen industrial production | Up to 450 bar | Up to 6.525 psi |

| Hydrogen filling stations | Up to 450 bar | Up to 6.525 psi |

applications and performances

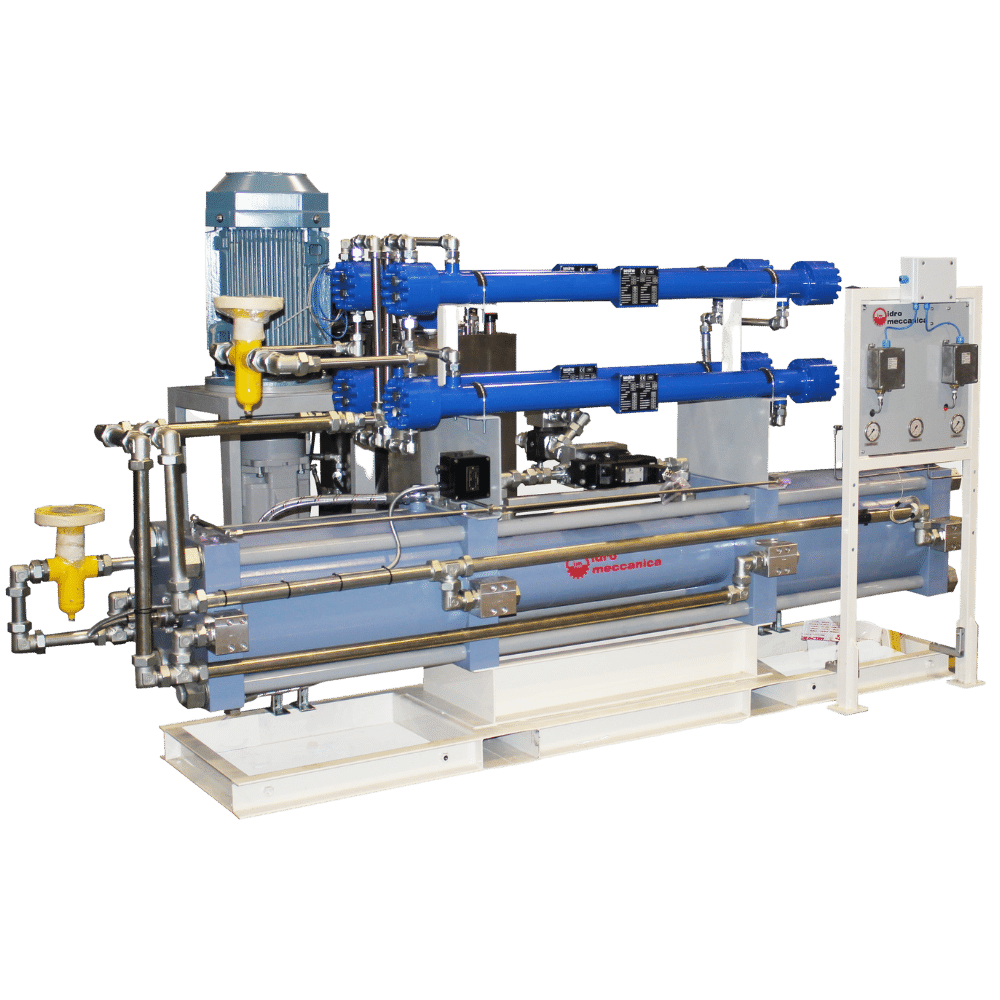

MDE/H series compressors

The right solution for

- High pressure and high flow applications

- Grid injection

| Suction pressure | Bar (psi) | 4 ÷ 450 (58 ÷ 6.525) |

| Max discharge pressure | Bar (psi) | 450 (6.525) |

| Max flowrate | Nmc/h (SCFM) | 3.500 (2.180) |

| Max power | kW (HP) | 75 (100) |

| Cylinders | No. | 1 |

| Stages | No. | 1 |

| Max speed | rpm | 80 |

| Maintenance interval | hours | 5.000 |

Twin configuration with 2-cylinder and double capacity available

applications and performances

DDE series compressors

Suitable for

- A first compression phase from the generator

- Grid injection

| Suction pressure | Bar (psi) | 14 ÷ 32(203 ÷ 464) |

| Max discharge pressure | Bar (psi) | 280 (4.060) |

| Max flowrate | Nmc/h (SCFM) | 2.000 (1.245) |

| Max power | kW (HP) | 75 (100) |

| Cylinders | No. | 1 |

| Stages | No. | 2 |

| Max speed | rpm | 80 |

| Maintenance interval | hours | 5.000 |

Twin configuration with 2-cylinders and double capacity available.

applications and performances

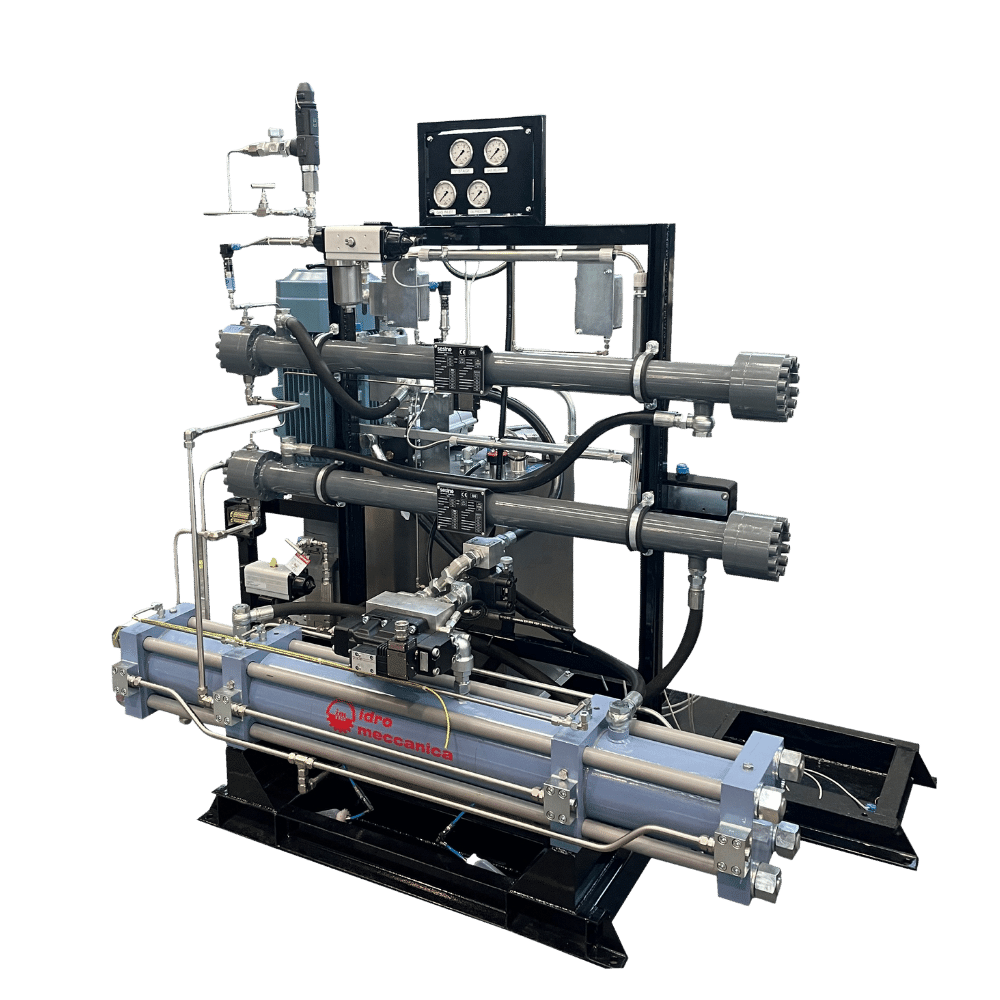

TDE/H series compressors

The best fit for

- Daughter stations

- Direct refilling stations

| Suction pressure | Bar (psi) | 14 ÷ 450 (145 ÷ 6.525) |

| Max discharge pressure | Bar (psi) | 450 (6.525) |

| Max flowrate | Nmc/h (SCFM) | 1.500 (935) |

| Max power | kW (HP) | 75 (100) |

| Cylinders | No. | 1 |

| Stages | No. | 3 |

| Max speed | rpm | 80 |

| Maintenance interval | hours | 5.000 |

Twin configuration with 2-cylinders and double capacity available.

Working together to achieve objectives with respect to the technical requirements of a project - that's what we do best.