Why use Idro Meccanica compressors?

Green solution, 100% oil free

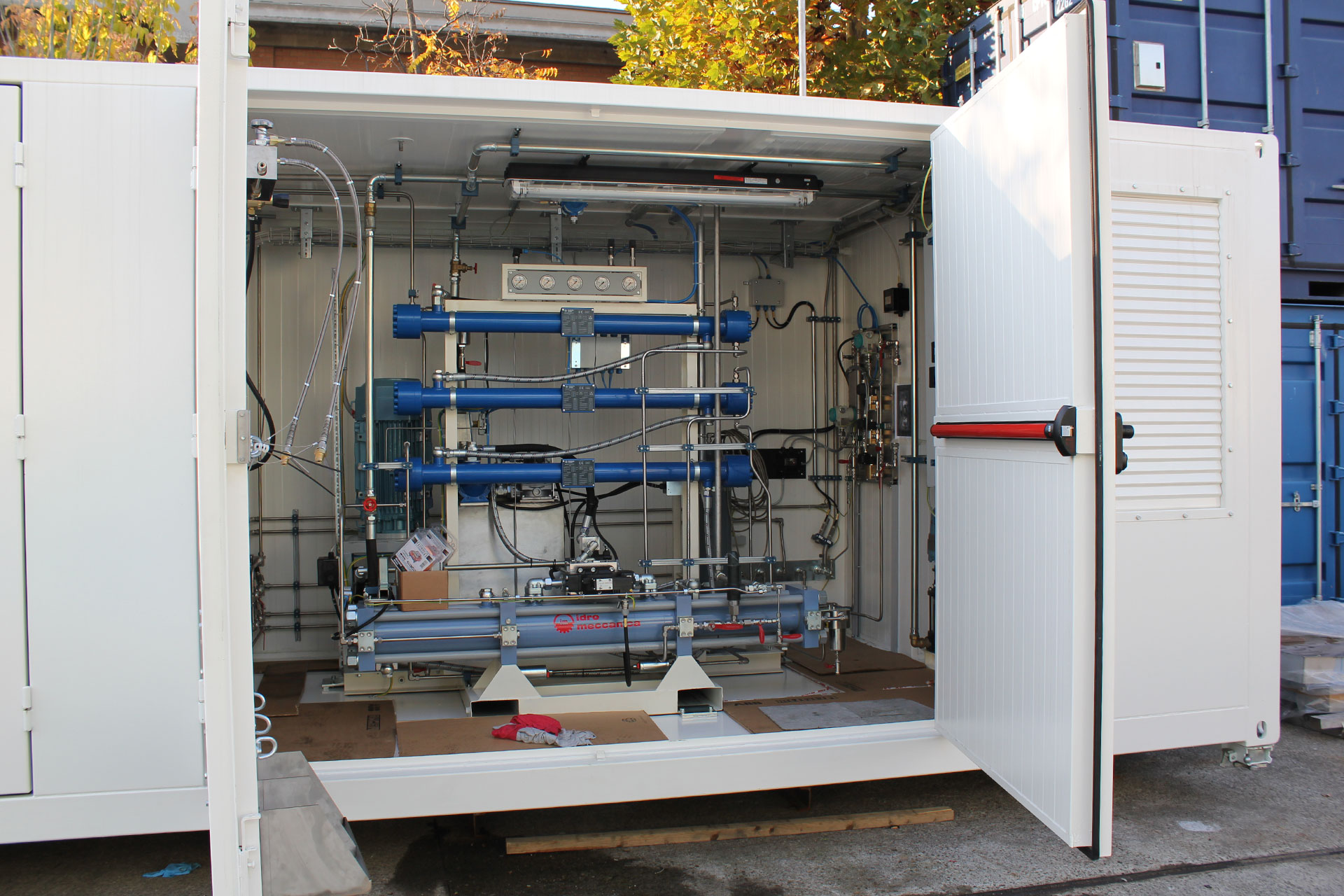

The gas and hydraulic sections are separated by a distance piece and two sets of seals – one on the gas and one on the oil side. Thanks to this system, the gas handled is pure, without any oil carryover.

In our latest generation of compressors, we have introduced a larger distance piece – Long Distance Piece (LDP) – that prevents any oil carry-over in the gas flow.

The portion of the piston rod that enters the hydraulic cylinder never reaches the gas section.

These units are used in the compression of hydrogen, making it clean and 100% oil free.

A compressor with high availability and reliability

Idro Meccanica compressors have a very low maintenance requirement.

Seals must be replaced between 3,000/5,000 operating hours, depending on the quality of the gas and the level of scheduled maintenance. The same applies to gas cartridges and hydraulic oil. In addition, the very low vibration due to the low speed (maximum 80 rpm) at which the compressor units operate results in high unit reliability.

The highest operating flexibility

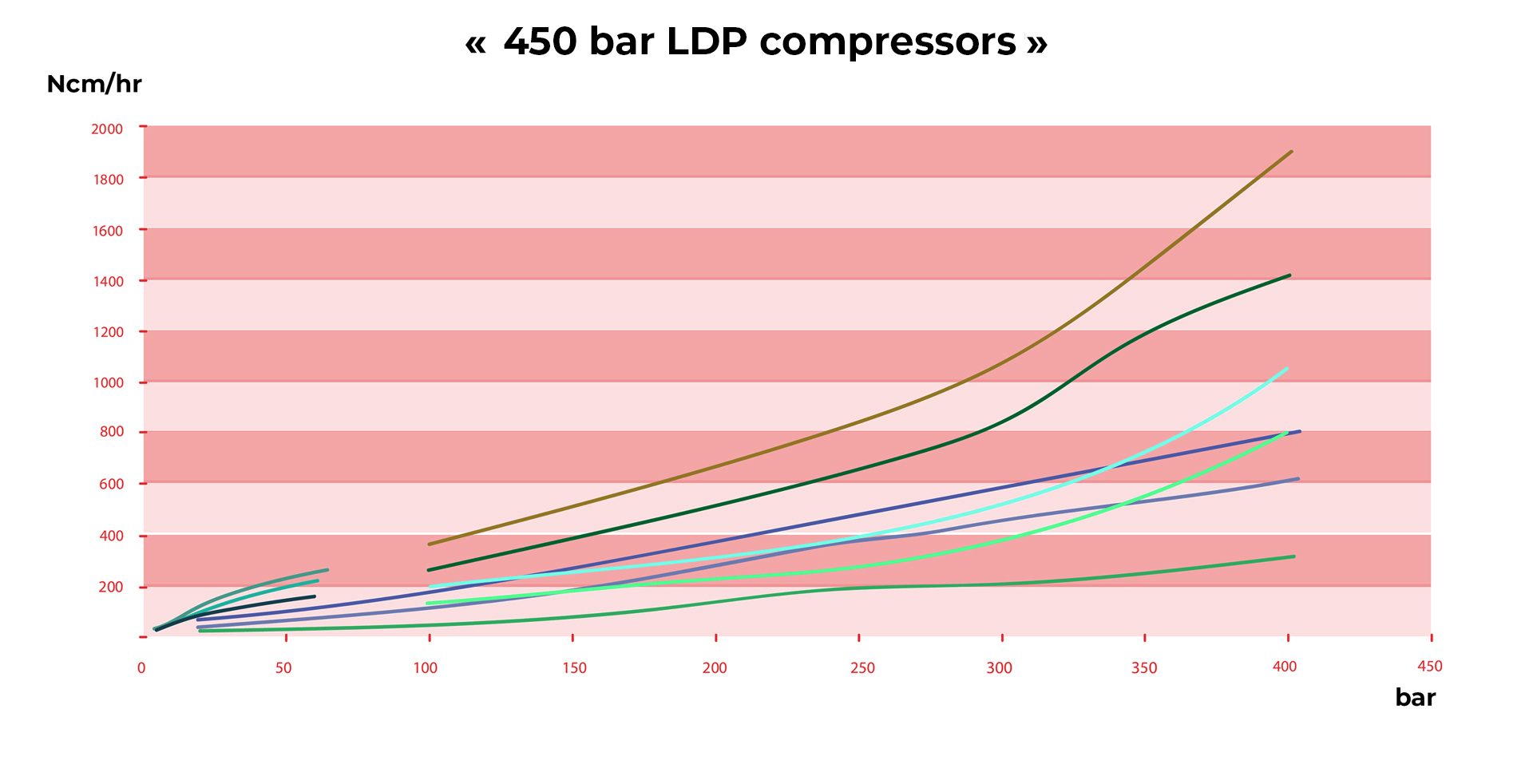

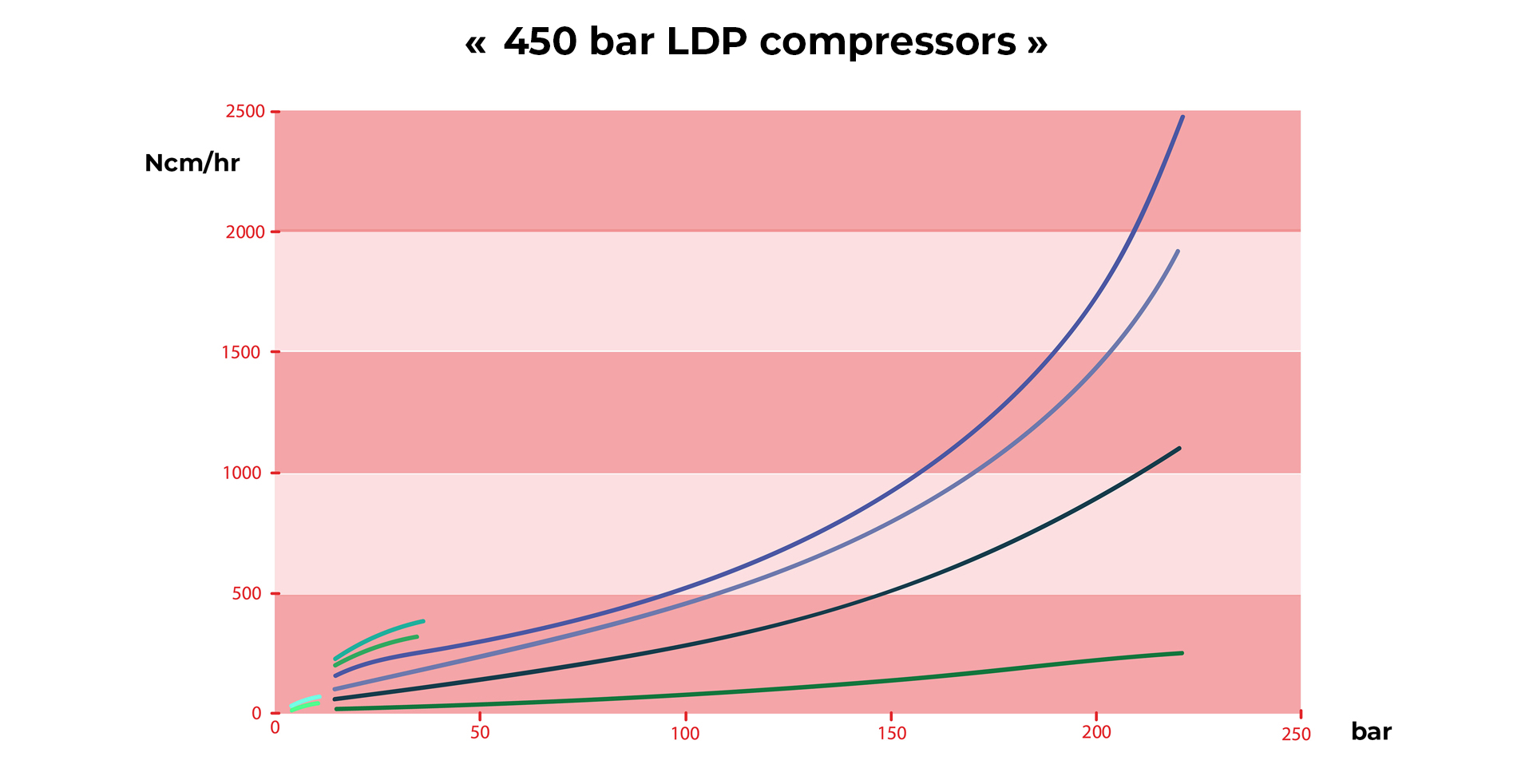

Our compressor units can operate with various gases other than hydrogen: biomethane, CNG and other synthetic gases – always guaranteeing a wide range of pressures at both suction and discharge.

The technology used allows Idro Meccanica units to compress all gases (excluding oxygen) up to 450 bar, thus setting a record in operational flexibility

An efficient and sustainable solution

Our compressors operate at low speed with very low energy consumption.

This, together with the wide pressure range covered, makes them the ideal solution in terms of high efficiency and low operating costs.

Proudly 'Made in Italy

The spirit of Idro Meccanica since the beginning was to customize each single project. Today, as part of the Group, we are capable of making a difference in the global energy transition.

Today, we maintain the same spirit of openness and accessibility to the market and to every single project.