Our solutions for gas management and distribution

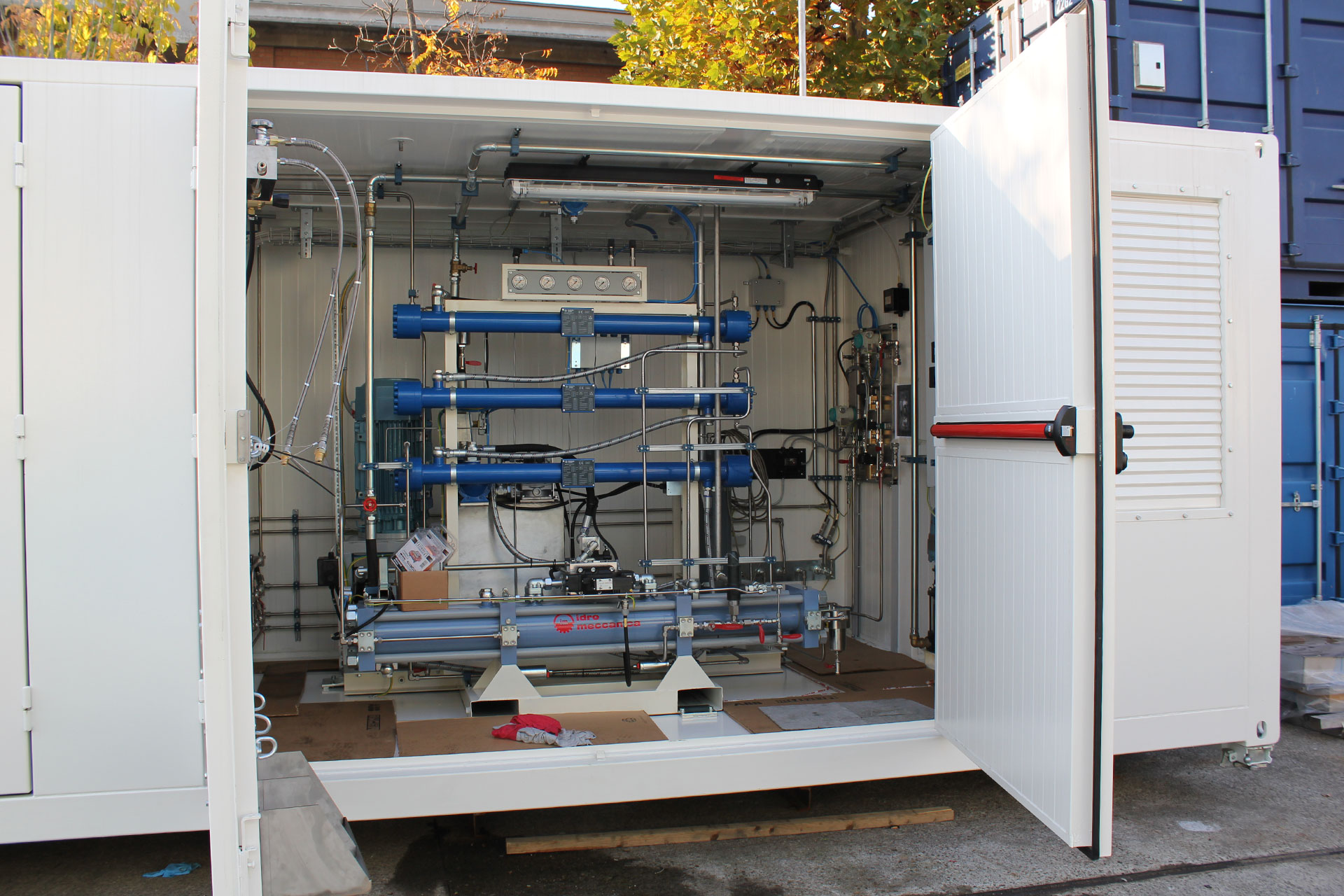

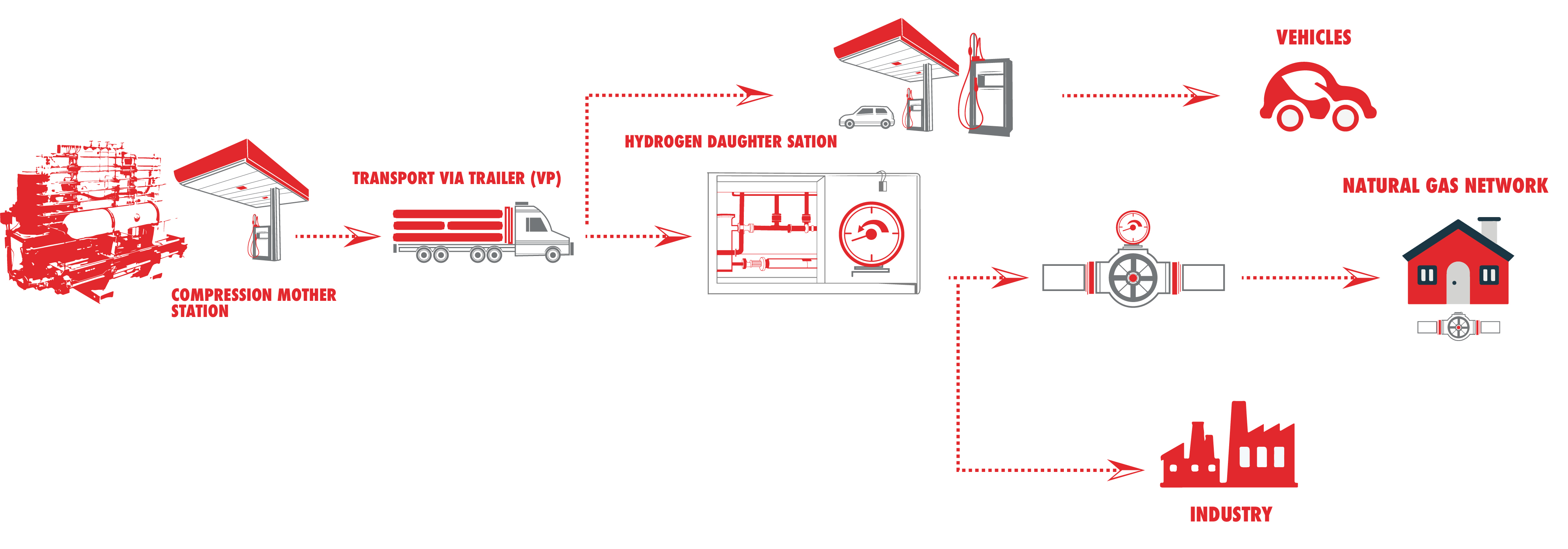

Daughter stations

Daughter stations are filling stations not connected to a pipeline. When gas is not produced on site – they offer an excellent solution to bring the filling stations closer to the customer. For greater accessibility, they are often installed along major pipeline net. The gas is brought to the station by means of mobile storages to meet the customer’s needs. Idro Meccanica boosters are designed for a wide range of inlet pressures.

Grid injection stations (hydrogen and biomethane)

Renewable energy production is linked to external, unpredictable weather factors. The opportunity to store the energy produced as hydrogen to be used when needed is the key to decarbonisation.

Feeding hydrogen into the grid together with CNG (volume blending) is one of the most effective solutions to rationalise electricity dispatch and transform energy produced from renewable sources into easy-to-manage green hydrogen using existing infrastructure.

Biomethane production also depends on external factors: it can vary depending on the raw biomass, digestion efficiency and upgrading. Our units can be equipped with hydraulic control of the flowrate from 0 to 100 per cent in order to follow gas production under all operating conditions ensuring the best system’s efficiency.

Hydrogen refilling stations

There are different configurations for hydrogen filling stations:

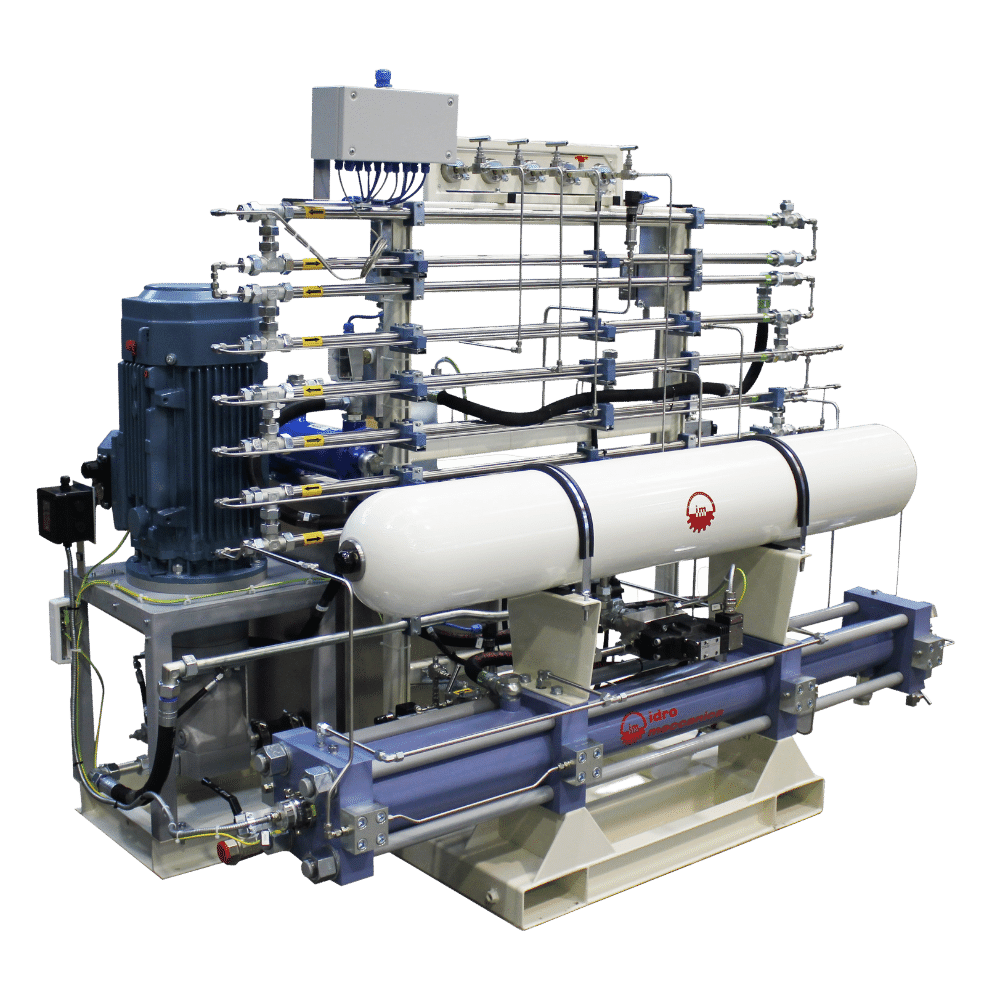

Daughter stations: we install a booster that can take the full pressure of the trailer (250 bar) and empty it as much as possible (usually up to 20 bar). We can use the TDH85 to reach 450 bar or our DDE85, DDE13 and TDE13 together with the MDH85 high-pressure booster.

Production stations: This is where the hydrogen is produced on site. The compressor must suck directly from the generator through a buffer. For productions we use our TDH85 booster, for larger productions a compressor + booster in twin version is recommended. The application is sized according to the performance of the hydrogen generator.

When the capacity of the TDH booster is not enough, we supply a two-cylinders unit in order to double the flowrate.

To date we have 100 hydrogen filling stations in operation.